How to make floating fish feed at home?

The use of floating fish feed has increased significantly over the past few decades, as it is a premium, eco-friendly floating fish feed with superior water stability, better flotation characteristics, less pollution, and zero waste. All these make floating fish feed an unstoppable trend in the development of the aquafeed industry.

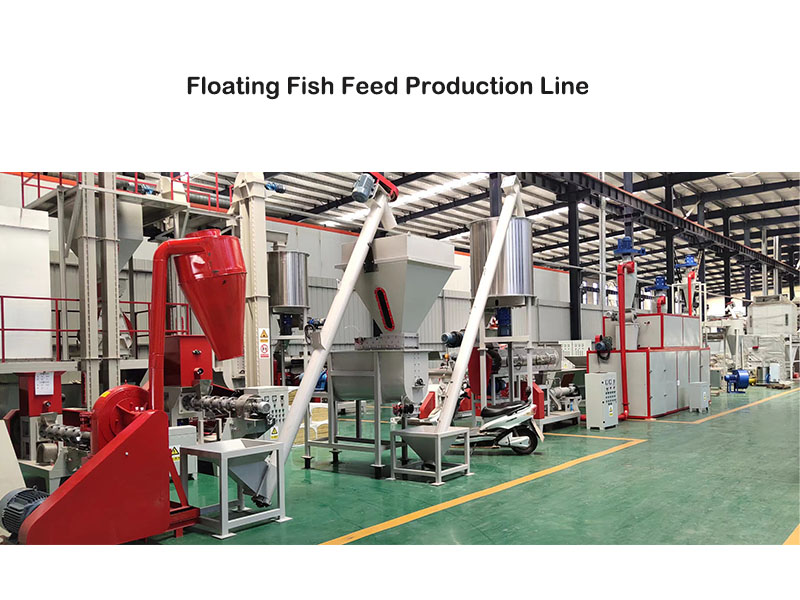

Own production of floating fish feed has become the choice of more and more aquaculture and farm owners, and the own production of floating fish feed is an important factor in large-scale fish farming and aquaculture. Lima feed machinery is a professional floating fish feed making machine equipment manufacturer. Not only offer single sinking/floating fish feed making machine but customize solution and design of fish feed production line. The self-produced floating fish feed can not only effectively reduce the cost of breeding, but also greatly improve the efficiency of fish growth. Today, I will share with you the experience of How to make floating fish feed at home by fish feed making machine, and I hope it will be helpful to you.

1. First you need to have a floating fish feed formulation, a floating fish feed machine,and prepare the materials for the floating fish feed pellet

1)Fish feed-making formula:

16.5% fish meal, 20% soybean meal, 8% peanut meal, 21% vegetable meal, 5% rice bran, 23% high-gluten flour, 2% calcium dihydrogen phosphate, 2% premix, 1.5% fish oil, 1% soybean lecithin .

2) Grinded The raw materials into powder:

The raw materials of floating fish feed pellets can be corn, wheat, soybeans, grains, bone meal, etc. Before making floating fish feed. It is necessary to use a fish feed pulverizer to pulverize the raw materials into powder. Raw materials need to be grinded into 60 to 80 meshes, raw materials moisture content: 20-25% rice meal contains about 10-14% of protein and also contains vitamin B1, B2, B6, and a small quantity of enzyme.

2. Production principle of floating fish feed machine:

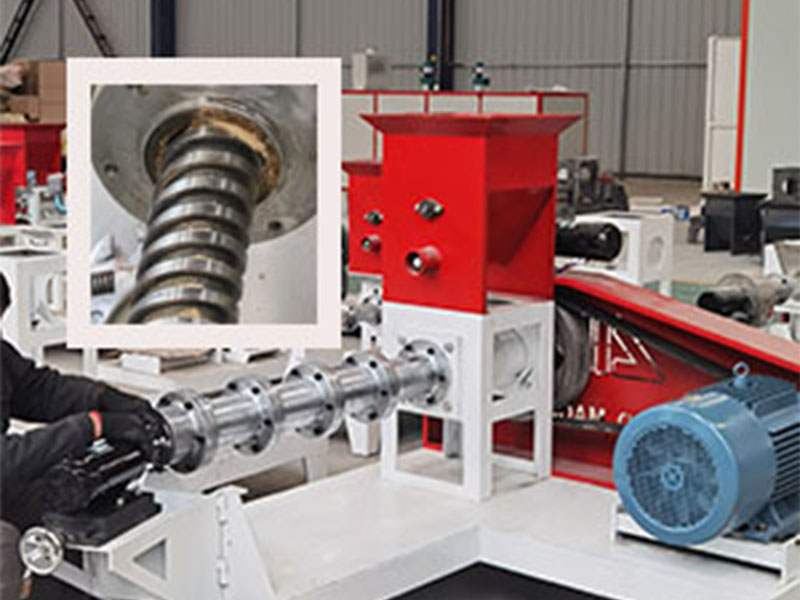

Floating fish feed is extruded feed. It is a feed processing technology: the expansion of feed in the extrusion cavity is actually a high-temperature transient process, that is, the feed is under high temperature, high pressure, high shear force, and high moisture environment. Then through continuous mixing, conditioning, heating, pressurization, curing, extrusion of die hole, and sudden pressure reduction to form a bulky and porous feed.

Extrusion and granulation generally use a wet-type floating fish feed machine. The raw material is extruded and pushed by a screw in the extruder to generate high temperature and high pressure. At the moment of passing through the die hole, the temperature and pressure drop sharply, causing the moisture in the raw material to rapidly increase. Evaporation, volume expansion, and specific gravity become lighter, and it is cut and formed through the incision of the material port.

Production principle of floating fish feed machine

3. Steps of making floating fish feed by floating fish feed machine

1). Fist Step: crushing raw material: Floating fish feed crusher machine

Raw material ingredients should be grinded to the required size by a feed grinder. the hammer mill has the same function, also called Wide chamber Fine feed Hammer mill, is mainly applied to fine grinding of meals for special aqua feed.

2). Second Step: mixing raw material: feed mixer machine

Mixing the raw material thoroughly can ensure extruding efficiency and improve feed quality. the feed mixer can be customized with atomizing spraying system which will add liquid like molasses and grease to the material more evenly.

3). Third Step: extruding raw material: floating fish feed extruder machine

Our floating fish feed machine can be divided into two types: dry type floating fish feed machine and wet type floating fish feed machine. Which needs to be used with the steam boiler to inject the steam when pelletizing. The dry type floating fish feed machine is cheaper while the capacity of the wet type floating fish feed machine is higher, so usually, the wet type fish feed extruder is suitable for large feed pellet factories, and the dry type fish feed processing machine is better and economic for the small and medium size user or factory.

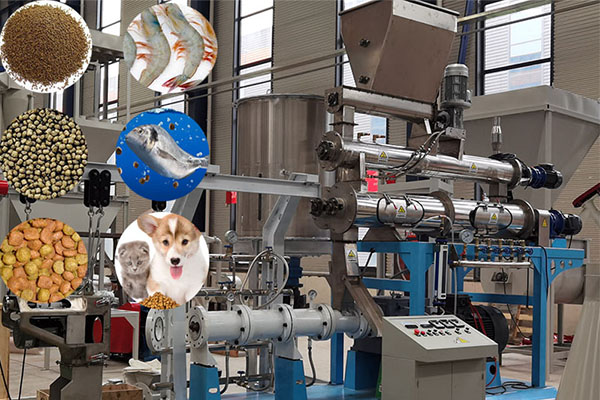

Note: this aqua floating fish feed machine can make fish feed, shrimp feed, catfish feed, golden fish feed, etc kinds of fishes and also pet foods

4). Fourth Step: drying floating fish feed pellets: fish feed pellet dryer

Our mesh belt dryer is a continuous convective belt dryer. Pellets formed through the extruder are stacked in layers on a wire mesh or perforated plate belt conveyor and conveyed continuously through drying chambers. During this process, the drying air is passed repeatedly through the product layer until pellets have the optimum moisture content before leaving the dryer. While if you choose wet-type floating fish feed machine, we recommend the gas-type pellet dryer.

5). Fifth Step: cooling final floating fish feed pellets: fish feed pellet cooler

Floating fish feed pellet cooling. When the temperature of the oil-sprayed pellets increases, they become soft, and can easily break. To avoid loss in this regard, the floating fish feed pellets must be cooled, and are consequently hardened. The cooling type adopted by most floating fish feed pellets plants is the counter flow cooler where the floating fish feed pellets are in opposite direction to the air cooling them.

6). Sixth: packing final floating fish feed pellets: automatic packing floating fish feed machine

To make the finished floating fish feed pellets easy to store, transport, and catch the client’s eyes, they should be packed properly. With our electronic weighing and packing machine, the finished floating fish feed pellets can be packed into bags, weighed, conveyed, and sealed automatically, which saves labor and time greatly and meet the requirements of large-scale production.

For this automatic packing floating fish feed machine, automatic heat typing code, automatic bag sewing, and automatic thread cutting can be optional functions.

4. Advantages of Lima floating fish feed making machine

1) With different molds, the floating fish feed machine for sale can produce different diameter feed pellets, from 0.5mmto 10 mm. The floating fish feed pellets can meet different stages of fish. The fish feed pellets can be floating for 24 hours.

2) The floating fish feed machine for sale can produce different shapes of feed for fish, crab, shrimp, dogs, cats, pets, etc. Through the pretreatment of the feed, it can reduce the loss of nutrition and advance the protein ratio. So the feed will be digested easily by animals.

3) The floating fish feed machine has high efficiency, low power consumption

4) Screw sleeve of the floating fish feed machine adopts enchase alloy steel strip structure, which guarantees long service life.

5. Benefits of floating fish feed pellet

1). Floating fish feed pellets can float on water for about 24 hours

Floating fish feed pellets produced by a floating fish feed machine can float on water for about 24 hours, which is convenient for feeding, and also save labor. due to the puffed floating, fish feed pellets can float on water, it can observe the feeding condition of the fish well after feeding, and it is convenient to adjust the feeding amount according to the feeding condition;

at the same time, people can accurately know the growth and health of fish by feeding amount and the condition of fish feeding, The fish farmer can calculate the amount of feed that can be fed according to the variety, specification, quantity, water temperature and feed rate of the fish

2). Puffed Floating Fish Feed Pellets Can Improve Feed Utilization

Due to the high temperature and high-pressure processing conditions of the floating fish feed machine, the starch in the feed is matured, and the fat is more conducive to digestion and absorption, thereby improving the palatability and digestion absorption of the feed. In addition, due to the physical and chemical changes

in the puffing process, the powder ratio of puffed floating fish feed pellets is generally within 1%, which directly improves the effective use of the feed. Under normal circumstances, fish cultured with puffed floating feed can save 5-10% of feed compared with powder of flour feed or other pellet feed.

3). Puffed Floating Fish Feed Pellets Can Protect Water Environment

Puffed floating fish feed pellets can reduce the pollution of water quality. The floating fish feed manufactured by this fish pellet making machine will not dissolve in the water for a long time, and the high-quality floating fish feed can float for about 24 hours and it is easy to observe and control the feeding, etc. It is extremely beneficial to environmental protection and to the growth of fish.

The use of floating fish feed has increased significantly over the past few decades, as it is a premium, eco-friendly fish feed with superior water stability, better flotation characteristics, less pollution, and zero waste. All these make it an unstoppable trend in the development of the aquafeed industry.

Lima Feed Machinery as a floating fish feed machine manufacturer exported our floating fish feed machine to South Africa, Philippines, India, Malaysia, Australia, Pakistan, Nigeria, Turkey, Chile, Maputo, Tanzania, Zimbabwe, America, Venezuela, Thailand, Myanmar, Vietnam, etc almost all over the world. Welcome to contact me to start a fish feed production business plan!

Back to List